1993

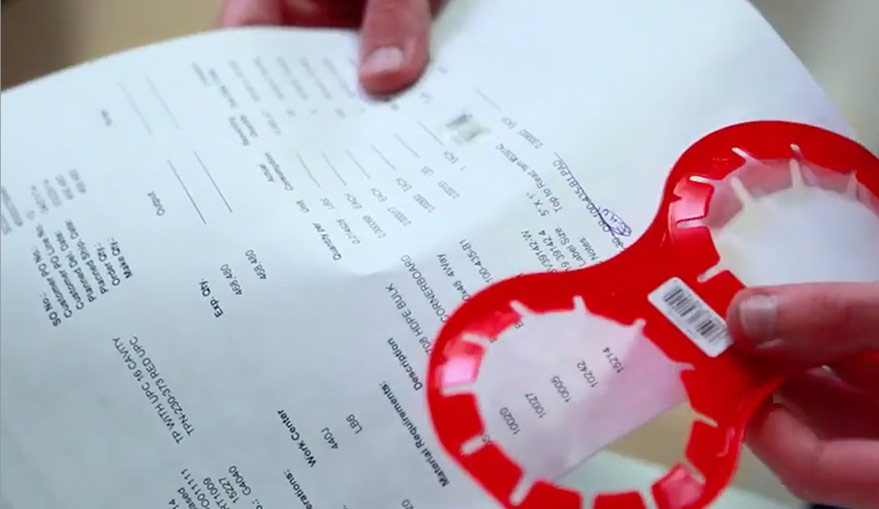

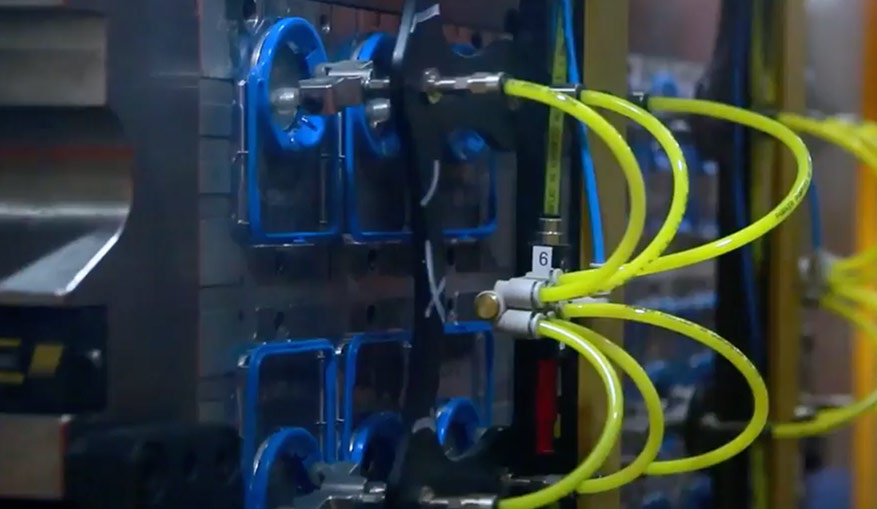

In 1993 a local Eugene, OR dairy reaches out to Jim Borg, local plastic injection mold maker. The dairy was seeking market entry into a new club store concept called Costco. They wanted a way to sell 2 milk gallons without putting them into a box. Jim designed the first TwinPak carrier for the dairy industry. Within 4 years, other large bottle products sought club store entry. Jim worked to get TwinPak handles onto larger national brands such as Treetop, Welch’s, and eventually Costco’s label Kirkland.